Description

What is PE film?

PE film in general (also known as shrink film, tight film) is a very thin and tough plastic film, capable of adhesion on all surfaces: wood, plastic, ...

PE stretch film stands for Polyethene which is produced under suitable pressure and temperature conditions.

PE film is also divided into many types, and each type has its own properties and characteristics depending on the purpose of use. However, it can be divided into two categories as follows:

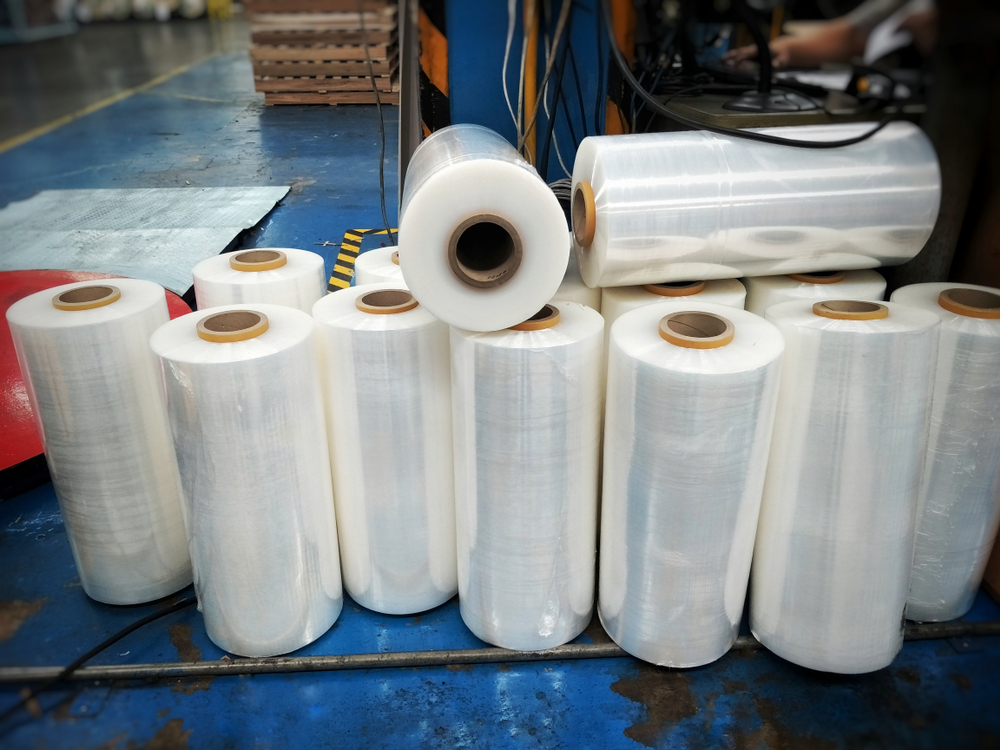

- Hand wrap film: This product is for manual packaging, so it will be light in weight. Customers who use this product often use it for simple packaging, small size for convenient operation.

- Wrapping machine wrap: This is a product for industrial packaging. The size and weight of each roll is usually very large depending on the type of machine that the customer is using

Application of PE stretch film

- PE film is used to wrap goods, book bags, boxes.

- With different thickness, it can be used to cover rain, shield agricultural products and crops.

- In life, you can use PE film to wrap food, wrap food, preserve it longer.

- Specialized PE film in the furniture industry is used to cover furniture and furniture when moving to avoid scratching of goods.

Shrink film production process and materials used

The nature of the perforated film is virgin plastic, so the quality of the crop depends entirely on the high-quality raw materials we use. The product must meet certain criteria such as being free of impurities, achieving a certain degree of clarity, good elasticity, etc.

Next comes the running part, which is operated automatically, including the following steps:

- Put ingredients into a container, there is a suction machine to put the ingredients in.

- Raw materials will be melted and passed through a filter to remove all impurities.

- Then the plastic will be poured into the mold and stretched according to the thickness required by the customer.

- Then the film will be cooled

- The final step to the finished product: the shrink film will be rolled into the core to complete the product.